BLOG DETAILS

BLOG DETAILS

BLOG DETAILS

Autonomous Construction Vehicles Working Without Operators: The Future of Government Infrastructure

Autonomous Construction Vehicles Working Without Operators: The Future of Government Infrastructure

Autonomous Construction Vehicles Working Without Operators: The Future of Government Infrastructure

Dec 5, 2025

/

Savik Infra

/

12 min

Dec 5, 2025

/

Savik Infra

/

12 min

Dec 5, 2025

/

Savik Infra

/

12 min

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own — guided by artificial intelligence, automation systems, and real-time data. These autonomous construction vehicles are reshaping how infrastructure is built, improving efficiency, safety, and precision on a scale never seen before. For companies like Savik Infra, which contribute to major government projects such as bridges, railways, highways, and public infrastructure, understanding this technology is not just about modernization — it is about preparing for the next era of construction.

Autonomous construction vehicles are no longer science fiction. They are already being tested, deployed, and integrated into infrastructure development around the world. From driverless dump trucks to automated road rollers and self-guided excavators, these machines are slowly transforming how heavy civil engineering work is carried out. In government projects where timelines, safety, and accuracy are critical, these vehicles have the potential to become an essential part of future construction ecosystems.

What Exactly Are Autonomous Construction Vehicles?

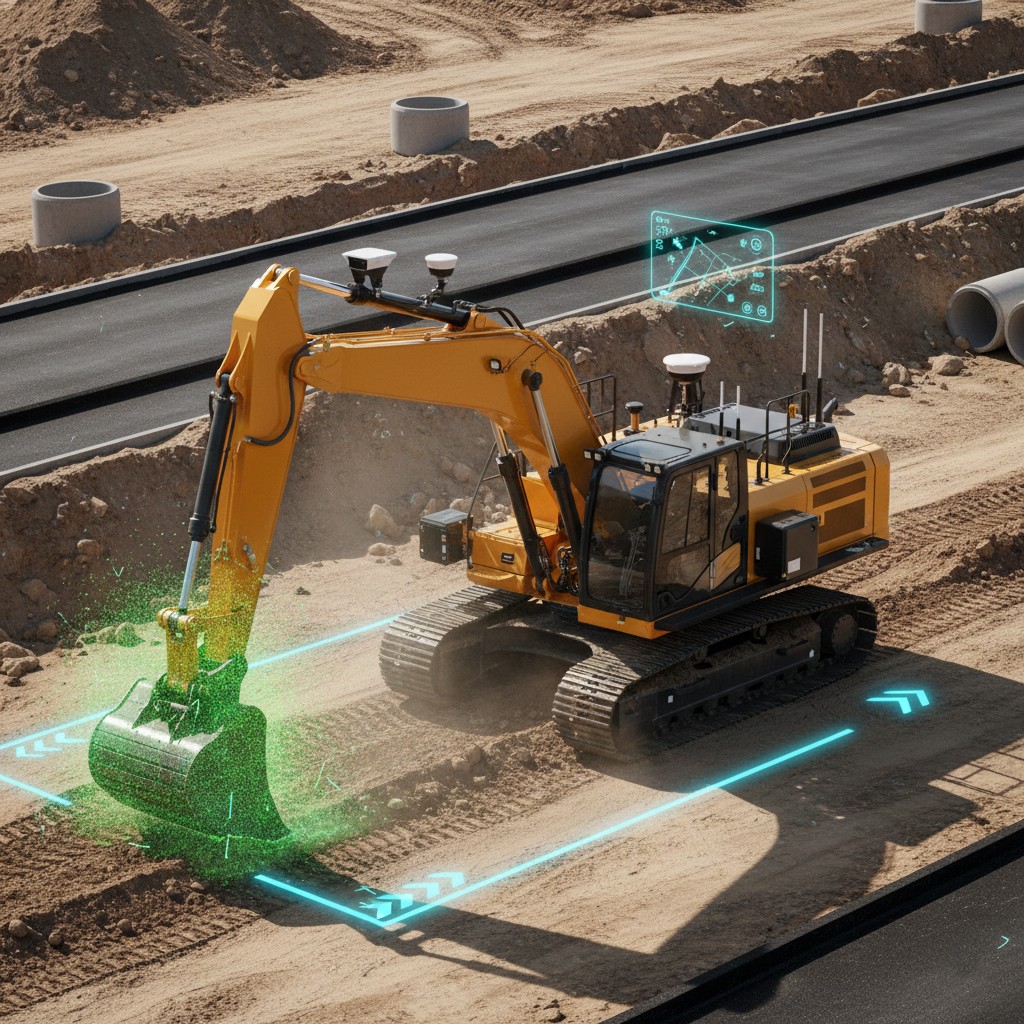

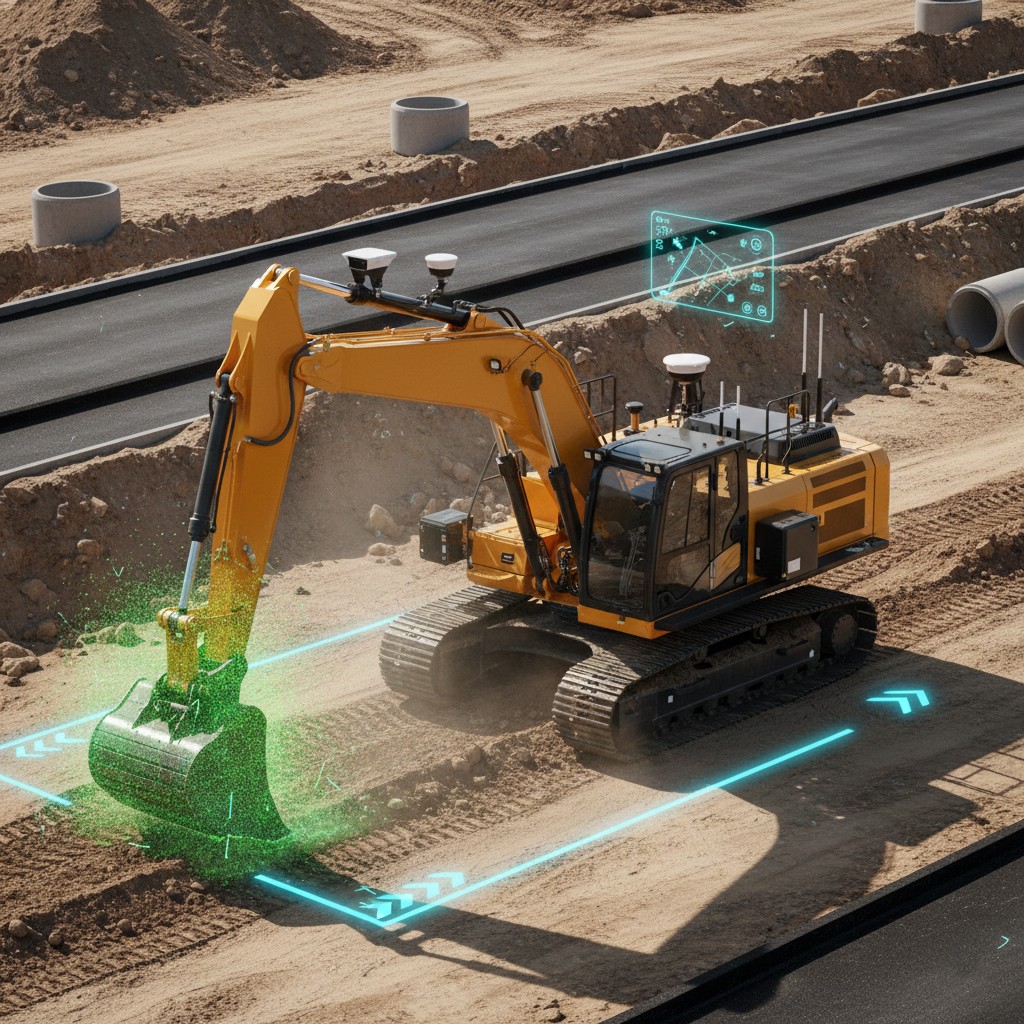

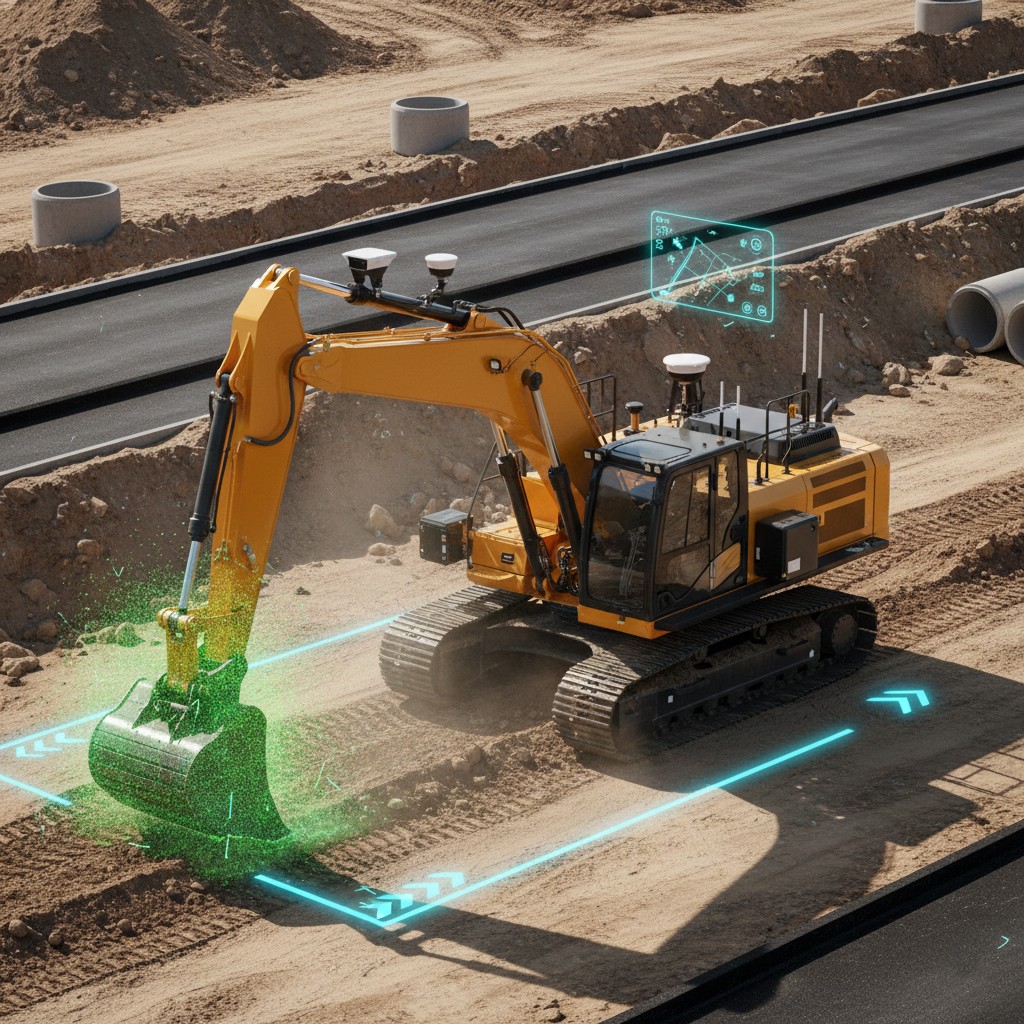

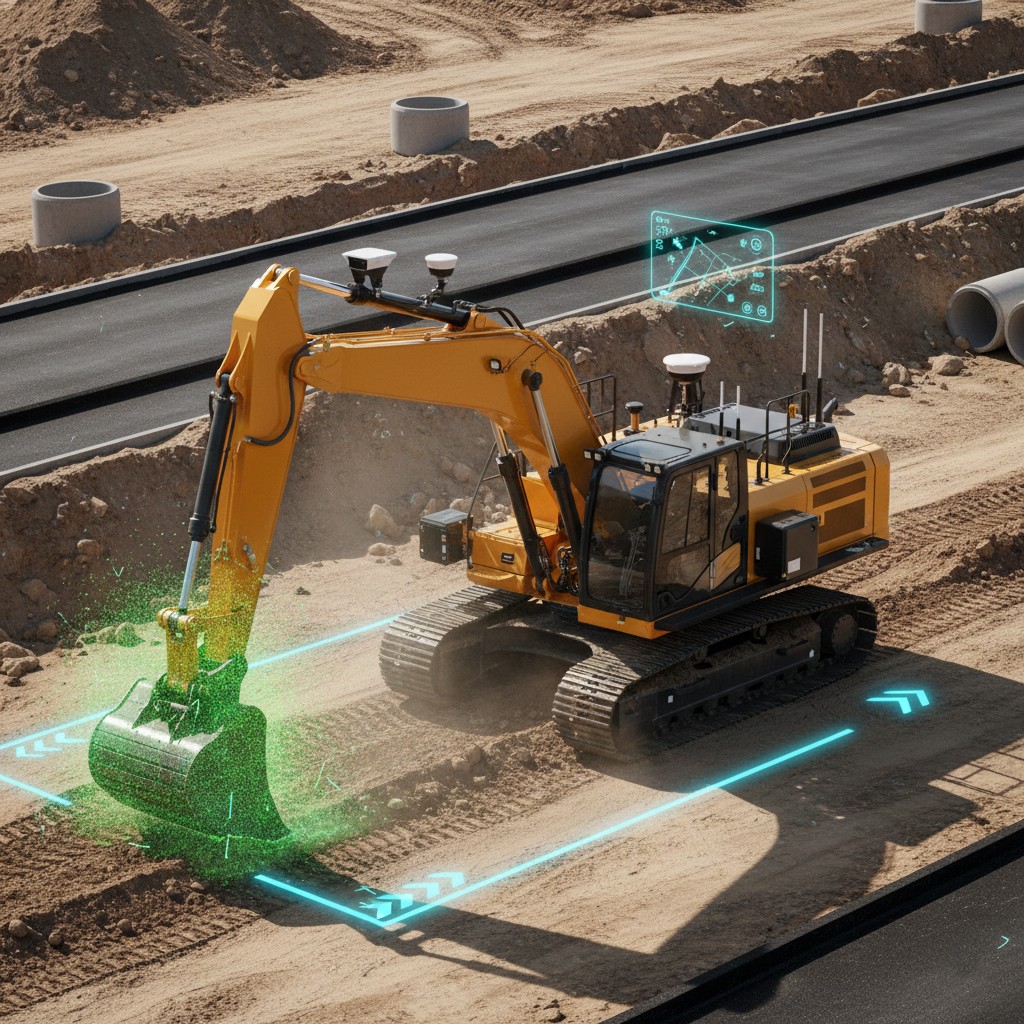

Autonomous construction vehicles — often referred to as ACVs — are machines capable of performing tasks without human drivers or operators. They use a combination of advanced technologies to navigate their environment, perform tasks, and communicate with other machines on the site. These technologies include GPS guidance, LiDAR scanners, high-precision sensors, onboard computers, and artificial intelligence systems that allow the vehicle to “see,” “think,” and “act” on its own.

In a traditional construction site, operators manually handle all the movements and operations of heavy machinery. But autonomous vehicles operate based on programmed pathways, digital site maps, and real-time instructions. They can excavate soil, transport materials, level ground, and compact surfaces with consistent accuracy, improving the overall quality of construction.

How Autonomous Vehicles Operate on a Construction Site

Autonomous construction vehicles function through a synchronized network of sensors and control systems. First, engineers map the construction site using drones, GPS coordinates, and digital surveying tools. This data is then fed into the vehicle’s onboard computer, which creates a virtual path and sets of instructions. As the vehicle works, its sensors constantly scan the environment to detect obstacles, slopes, edges, and terrain changes. If it identifies a potential hazard, it automatically adjusts its path or stops operations.

Most autonomous vehicles are semi-autonomous at the beginning. They work with remote monitoring systems where an engineer supervises their activities from a command center. Over time, as AI algorithms learn the site conditions, the machine becomes more independent. With each operation, it builds a better understanding of the terrain and improves its precision.

Why the Construction Industry Is Moving Toward Automation

For large-scale infrastructure projects, efficiency and accuracy are non-negotiable. Human errors, fatigue, weather conditions, and complex tasks often slow down construction timelines. Autonomous vehicles reduce these challenges by offering consistent performance, high-quality output, and predictable timelines.

Automation also helps during operations that are repetitive or hazardous. For example, compacting road surfaces for long stretches, transporting heavy materials across uneven ground, or excavating deep trenches can be risky for human workers. Autonomous machines take over these tasks with enhanced safety and precision, allowing workers to shift to less dangerous, more analytical roles.

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own — guided by artificial intelligence, automation systems, and real-time data. These autonomous construction vehicles are reshaping how infrastructure is built, improving efficiency, safety, and precision on a scale never seen before. For companies like Savik Infra, which contribute to major government projects such as bridges, railways, highways, and public infrastructure, understanding this technology is not just about modernization — it is about preparing for the next era of construction.

Autonomous construction vehicles are no longer science fiction. They are already being tested, deployed, and integrated into infrastructure development around the world. From driverless dump trucks to automated road rollers and self-guided excavators, these machines are slowly transforming how heavy civil engineering work is carried out. In government projects where timelines, safety, and accuracy are critical, these vehicles have the potential to become an essential part of future construction ecosystems.

What Exactly Are Autonomous Construction Vehicles?

Autonomous construction vehicles — often referred to as ACVs — are machines capable of performing tasks without human drivers or operators. They use a combination of advanced technologies to navigate their environment, perform tasks, and communicate with other machines on the site. These technologies include GPS guidance, LiDAR scanners, high-precision sensors, onboard computers, and artificial intelligence systems that allow the vehicle to “see,” “think,” and “act” on its own.

In a traditional construction site, operators manually handle all the movements and operations of heavy machinery. But autonomous vehicles operate based on programmed pathways, digital site maps, and real-time instructions. They can excavate soil, transport materials, level ground, and compact surfaces with consistent accuracy, improving the overall quality of construction.

How Autonomous Vehicles Operate on a Construction Site

Autonomous construction vehicles function through a synchronized network of sensors and control systems. First, engineers map the construction site using drones, GPS coordinates, and digital surveying tools. This data is then fed into the vehicle’s onboard computer, which creates a virtual path and sets of instructions. As the vehicle works, its sensors constantly scan the environment to detect obstacles, slopes, edges, and terrain changes. If it identifies a potential hazard, it automatically adjusts its path or stops operations.

Most autonomous vehicles are semi-autonomous at the beginning. They work with remote monitoring systems where an engineer supervises their activities from a command center. Over time, as AI algorithms learn the site conditions, the machine becomes more independent. With each operation, it builds a better understanding of the terrain and improves its precision.

Why the Construction Industry Is Moving Toward Automation

For large-scale infrastructure projects, efficiency and accuracy are non-negotiable. Human errors, fatigue, weather conditions, and complex tasks often slow down construction timelines. Autonomous vehicles reduce these challenges by offering consistent performance, high-quality output, and predictable timelines.

Automation also helps during operations that are repetitive or hazardous. For example, compacting road surfaces for long stretches, transporting heavy materials across uneven ground, or excavating deep trenches can be risky for human workers. Autonomous machines take over these tasks with enhanced safety and precision, allowing workers to shift to less dangerous, more analytical roles.

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own — guided by artificial intelligence, automation systems, and real-time data. These autonomous construction vehicles are reshaping how infrastructure is built, improving efficiency, safety, and precision on a scale never seen before. For companies like Savik Infra, which contribute to major government projects such as bridges, railways, highways, and public infrastructure, understanding this technology is not just about modernization — it is about preparing for the next era of construction.

Autonomous construction vehicles are no longer science fiction. They are already being tested, deployed, and integrated into infrastructure development around the world. From driverless dump trucks to automated road rollers and self-guided excavators, these machines are slowly transforming how heavy civil engineering work is carried out. In government projects where timelines, safety, and accuracy are critical, these vehicles have the potential to become an essential part of future construction ecosystems.

What Exactly Are Autonomous Construction Vehicles?

Autonomous construction vehicles — often referred to as ACVs — are machines capable of performing tasks without human drivers or operators. They use a combination of advanced technologies to navigate their environment, perform tasks, and communicate with other machines on the site. These technologies include GPS guidance, LiDAR scanners, high-precision sensors, onboard computers, and artificial intelligence systems that allow the vehicle to “see,” “think,” and “act” on its own.

In a traditional construction site, operators manually handle all the movements and operations of heavy machinery. But autonomous vehicles operate based on programmed pathways, digital site maps, and real-time instructions. They can excavate soil, transport materials, level ground, and compact surfaces with consistent accuracy, improving the overall quality of construction.

How Autonomous Vehicles Operate on a Construction Site

Autonomous construction vehicles function through a synchronized network of sensors and control systems. First, engineers map the construction site using drones, GPS coordinates, and digital surveying tools. This data is then fed into the vehicle’s onboard computer, which creates a virtual path and sets of instructions. As the vehicle works, its sensors constantly scan the environment to detect obstacles, slopes, edges, and terrain changes. If it identifies a potential hazard, it automatically adjusts its path or stops operations.

Most autonomous vehicles are semi-autonomous at the beginning. They work with remote monitoring systems where an engineer supervises their activities from a command center. Over time, as AI algorithms learn the site conditions, the machine becomes more independent. With each operation, it builds a better understanding of the terrain and improves its precision.

Why the Construction Industry Is Moving Toward Automation

For large-scale infrastructure projects, efficiency and accuracy are non-negotiable. Human errors, fatigue, weather conditions, and complex tasks often slow down construction timelines. Autonomous vehicles reduce these challenges by offering consistent performance, high-quality output, and predictable timelines.

Automation also helps during operations that are repetitive or hazardous. For example, compacting road surfaces for long stretches, transporting heavy materials across uneven ground, or excavating deep trenches can be risky for human workers. Autonomous machines take over these tasks with enhanced safety and precision, allowing workers to shift to less dangerous, more analytical roles.

Building home, happy hearts

Building home, happy hearts

Innovative technology with building better development

Innovative technology with building better development

Discovering possibility and transparent communication

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

The Advantages of Autonomous Construction Vehicles

Higher Precision and Accuracy – Automated controls ensure perfect cuts, leveling, grading, and alignment.

Reduced Human Error – Eliminates mistakes caused by fatigue or misjudgment.

Continuous Operation – Machines can run day and night, allowing faster project completion.

Improved Worker Safety – Removes humans from dangerous zones and heavy-load activities.

Lower Operational Costs – Reduces fuel wastage, idle time, and unnecessary downtime.

Real-Time Monitoring – Engineers can track progress through dashboards and remote systems.

Scalability – Once systems are set up, multiple machines can operate simultaneously on large projects.

Environmental Benefits – Optimized routes and automated fuel controls reduce carbon emissions.

The Advantages of Autonomous Construction Vehicles

Higher Precision and Accuracy – Automated controls ensure perfect cuts, leveling, grading, and alignment.

Reduced Human Error – Eliminates mistakes caused by fatigue or misjudgment.

Continuous Operation – Machines can run day and night, allowing faster project completion.

Improved Worker Safety – Removes humans from dangerous zones and heavy-load activities.

Lower Operational Costs – Reduces fuel wastage, idle time, and unnecessary downtime.

Real-Time Monitoring – Engineers can track progress through dashboards and remote systems.

Scalability – Once systems are set up, multiple machines can operate simultaneously on large projects.

Environmental Benefits – Optimized routes and automated fuel controls reduce carbon emissions.

The Advantages of Autonomous Construction Vehicles

Higher Precision and Accuracy – Automated controls ensure perfect cuts, leveling, grading, and alignment.

Reduced Human Error – Eliminates mistakes caused by fatigue or misjudgment.

Continuous Operation – Machines can run day and night, allowing faster project completion.

Improved Worker Safety – Removes humans from dangerous zones and heavy-load activities.

Lower Operational Costs – Reduces fuel wastage, idle time, and unnecessary downtime.

Real-Time Monitoring – Engineers can track progress through dashboards and remote systems.

Scalability – Once systems are set up, multiple machines can operate simultaneously on large projects.

Environmental Benefits – Optimized routes and automated fuel controls reduce carbon emissions.

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own

The construction industry is undergoing a historic transformation. Machines that once depended entirely on human operators are now beginning to work on their own

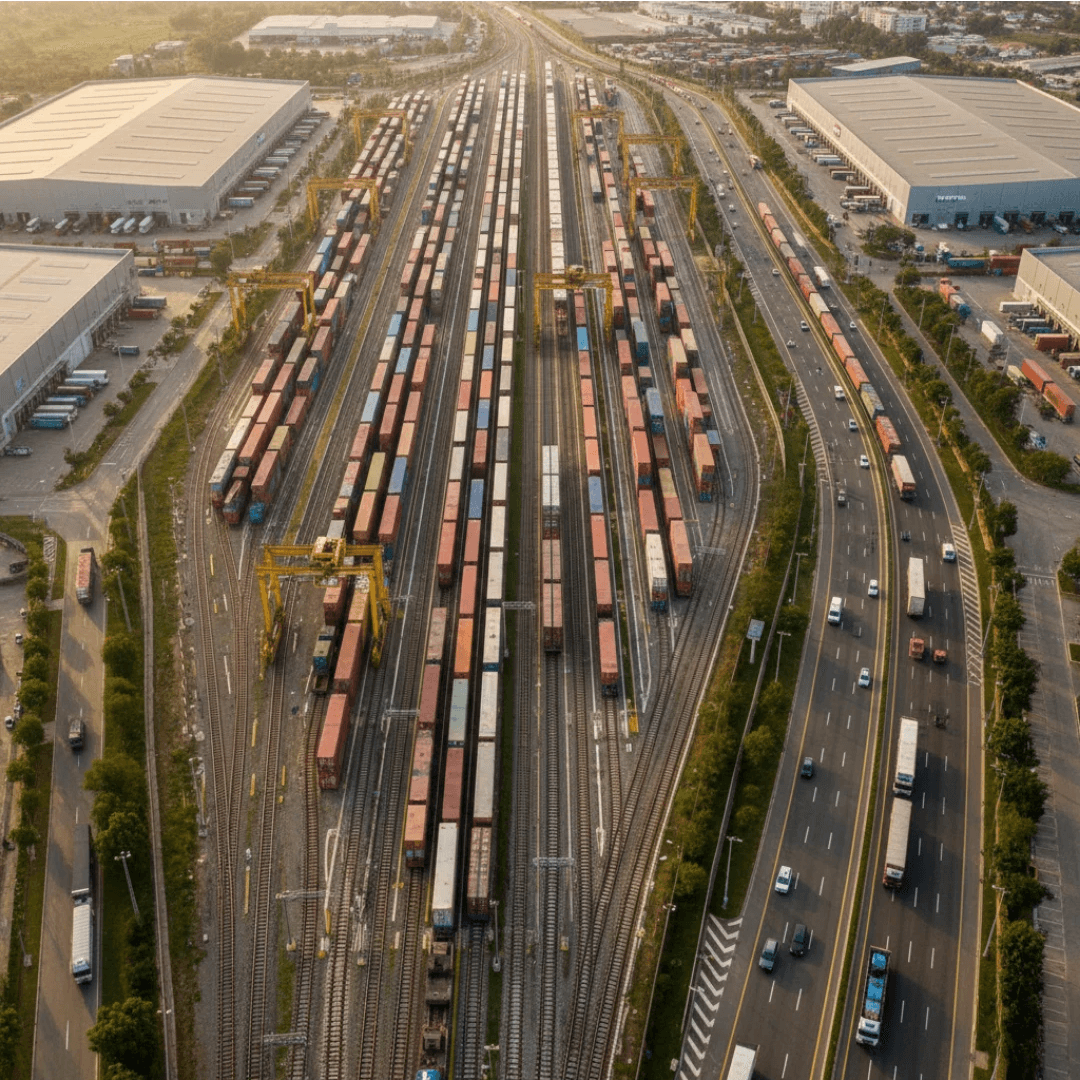

Transforming Government Infrastructure With Automation

Government infrastructure projects — highways, railways, bridges, canals, and public utilities — often involve massive land areas, strict deadlines, and heavy machinery. Autonomous construction vehicles bring a whole new level of capability to such projects. These machines can maintain uniform quality in road compaction, ensure precise measurements for railway embankments, and carry out repetitive tasks like earthmoving with unmatched consistency.

Imagine a future railway project where unmanned excavators dig the soil, automated rollers compress the track bed, and driverless trucks transport materials 24/7. Not only does this accelerate the pace of construction, but it also improves the accuracy and life span of the infrastructure. For a company like Savik Infra that participates in government tenders with strict compliance standards, embracing such technology can provide a competitive edge and long-term value.

Safety, Monitoring, and Compliance in the Autonomous Era

Safety remains one of the most important factors in construction — especially in government-funded projects. Autonomous vehicles reduce the likelihood of accidents by using sensors and AI algorithms that detect danger before it becomes a problem. They can automatically stop when a person enters a restricted zone or when an obstacle appears suddenly.

Every autonomous vehicle also generates real-time data about its operations. Engineers can monitor speed, load, distance covered, fuel usage, and performance metrics from a remote dashboard. This enhances transparency, accountability, and compliance with government quality standards. These systems ensure that every phase of construction is documented and traceable — a major advantage during audits and inspections.

The Technology Behind These Machines

Autonomous construction vehicles rely on a combination of robotics, machine learning, sensor systems, and satellite navigation. GPS and RTK (Real-Time Kinematic) networks enable centimeter-level accuracy, which is essential in bridge construction, rail alignment, and road grading. LiDAR and radar systems allow the machine to detect objects and map its surroundings with precision.

In addition, machine learning algorithms help the vehicle improve with each operation. It “remembers” soil patterns, obstacle locations, slopes, and previous tasks. This self-learning ability gives autonomous machines an advantage over traditional equipment, which must be manually controlled every time.

Challenges and Limitations

Despite the rapid growth of autonomous technology, there are challenges that need to be addressed. Construction sites are unpredictable environments where weather, terrain, and external factors can change quickly. Some areas, especially remote government project locations, may lack stable GPS connectivity. There are also regulatory and safety norms that must be updated to integrate operator-less machinery.

Training is another important element. Workers and site engineers must learn how to manage, monitor, and oversee automated operations. Rather than replacing workers, automation changes their roles — turning equipment operators into control-room supervisors and technical experts.

The Future of Autonomous Construction in India

India is witnessing major infrastructure growth through initiatives like Bharatmala, Sagarmala, Dedicated Freight Corridors, and Smart Cities Mission. As technology evolves, autonomous construction vehicles will soon become an integral part of large-scale government projects. Companies like Savik Infra that prepare early for this shift will gain a significant advantage in efficiency, quality, and delivery timelines.

In the coming years, we can expect automated excavators, robotic pavers, intelligent cranes, and self-driving trucks to become more common. These vehicles will work together through connected systems, forming fully digital construction sites where workflows are optimized through real-time data.

Conclusion

Autonomous construction vehicles are not just machines — they represent a new chapter in infrastructure development. By combining precision, safety, speed, and intelligent automation, they redefine how roads, railways, and bridges are built. For government contractors like Savik Infra, this technology can enhance productivity, maintain compliance, and ensure long-lasting public infrastructure. As automation continues to evolve, the construction sites of tomorrow will be smarter, safer, and more efficient — powered by machines that work without operators, guided entirely by technology.

Transforming Government Infrastructure With Automation

Government infrastructure projects — highways, railways, bridges, canals, and public utilities — often involve massive land areas, strict deadlines, and heavy machinery. Autonomous construction vehicles bring a whole new level of capability to such projects. These machines can maintain uniform quality in road compaction, ensure precise measurements for railway embankments, and carry out repetitive tasks like earthmoving with unmatched consistency.

Imagine a future railway project where unmanned excavators dig the soil, automated rollers compress the track bed, and driverless trucks transport materials 24/7. Not only does this accelerate the pace of construction, but it also improves the accuracy and life span of the infrastructure. For a company like Savik Infra that participates in government tenders with strict compliance standards, embracing such technology can provide a competitive edge and long-term value.

Safety, Monitoring, and Compliance in the Autonomous Era

Safety remains one of the most important factors in construction — especially in government-funded projects. Autonomous vehicles reduce the likelihood of accidents by using sensors and AI algorithms that detect danger before it becomes a problem. They can automatically stop when a person enters a restricted zone or when an obstacle appears suddenly.

Every autonomous vehicle also generates real-time data about its operations. Engineers can monitor speed, load, distance covered, fuel usage, and performance metrics from a remote dashboard. This enhances transparency, accountability, and compliance with government quality standards. These systems ensure that every phase of construction is documented and traceable — a major advantage during audits and inspections.

The Technology Behind These Machines

Autonomous construction vehicles rely on a combination of robotics, machine learning, sensor systems, and satellite navigation. GPS and RTK (Real-Time Kinematic) networks enable centimeter-level accuracy, which is essential in bridge construction, rail alignment, and road grading. LiDAR and radar systems allow the machine to detect objects and map its surroundings with precision.

In addition, machine learning algorithms help the vehicle improve with each operation. It “remembers” soil patterns, obstacle locations, slopes, and previous tasks. This self-learning ability gives autonomous machines an advantage over traditional equipment, which must be manually controlled every time.

Challenges and Limitations

Despite the rapid growth of autonomous technology, there are challenges that need to be addressed. Construction sites are unpredictable environments where weather, terrain, and external factors can change quickly. Some areas, especially remote government project locations, may lack stable GPS connectivity. There are also regulatory and safety norms that must be updated to integrate operator-less machinery.

Training is another important element. Workers and site engineers must learn how to manage, monitor, and oversee automated operations. Rather than replacing workers, automation changes their roles — turning equipment operators into control-room supervisors and technical experts.

The Future of Autonomous Construction in India

India is witnessing major infrastructure growth through initiatives like Bharatmala, Sagarmala, Dedicated Freight Corridors, and Smart Cities Mission. As technology evolves, autonomous construction vehicles will soon become an integral part of large-scale government projects. Companies like Savik Infra that prepare early for this shift will gain a significant advantage in efficiency, quality, and delivery timelines.

In the coming years, we can expect automated excavators, robotic pavers, intelligent cranes, and self-driving trucks to become more common. These vehicles will work together through connected systems, forming fully digital construction sites where workflows are optimized through real-time data.

Conclusion

Autonomous construction vehicles are not just machines — they represent a new chapter in infrastructure development. By combining precision, safety, speed, and intelligent automation, they redefine how roads, railways, and bridges are built. For government contractors like Savik Infra, this technology can enhance productivity, maintain compliance, and ensure long-lasting public infrastructure. As automation continues to evolve, the construction sites of tomorrow will be smarter, safer, and more efficient — powered by machines that work without operators, guided entirely by technology.

Transforming Government Infrastructure With Automation

Government infrastructure projects — highways, railways, bridges, canals, and public utilities — often involve massive land areas, strict deadlines, and heavy machinery. Autonomous construction vehicles bring a whole new level of capability to such projects. These machines can maintain uniform quality in road compaction, ensure precise measurements for railway embankments, and carry out repetitive tasks like earthmoving with unmatched consistency.

Imagine a future railway project where unmanned excavators dig the soil, automated rollers compress the track bed, and driverless trucks transport materials 24/7. Not only does this accelerate the pace of construction, but it also improves the accuracy and life span of the infrastructure. For a company like Savik Infra that participates in government tenders with strict compliance standards, embracing such technology can provide a competitive edge and long-term value.

Safety, Monitoring, and Compliance in the Autonomous Era

Safety remains one of the most important factors in construction — especially in government-funded projects. Autonomous vehicles reduce the likelihood of accidents by using sensors and AI algorithms that detect danger before it becomes a problem. They can automatically stop when a person enters a restricted zone or when an obstacle appears suddenly.

Every autonomous vehicle also generates real-time data about its operations. Engineers can monitor speed, load, distance covered, fuel usage, and performance metrics from a remote dashboard. This enhances transparency, accountability, and compliance with government quality standards. These systems ensure that every phase of construction is documented and traceable — a major advantage during audits and inspections.

The Technology Behind These Machines

Autonomous construction vehicles rely on a combination of robotics, machine learning, sensor systems, and satellite navigation. GPS and RTK (Real-Time Kinematic) networks enable centimeter-level accuracy, which is essential in bridge construction, rail alignment, and road grading. LiDAR and radar systems allow the machine to detect objects and map its surroundings with precision.

In addition, machine learning algorithms help the vehicle improve with each operation. It “remembers” soil patterns, obstacle locations, slopes, and previous tasks. This self-learning ability gives autonomous machines an advantage over traditional equipment, which must be manually controlled every time.

Challenges and Limitations

Despite the rapid growth of autonomous technology, there are challenges that need to be addressed. Construction sites are unpredictable environments where weather, terrain, and external factors can change quickly. Some areas, especially remote government project locations, may lack stable GPS connectivity. There are also regulatory and safety norms that must be updated to integrate operator-less machinery.

Training is another important element. Workers and site engineers must learn how to manage, monitor, and oversee automated operations. Rather than replacing workers, automation changes their roles — turning equipment operators into control-room supervisors and technical experts.

The Future of Autonomous Construction in India

India is witnessing major infrastructure growth through initiatives like Bharatmala, Sagarmala, Dedicated Freight Corridors, and Smart Cities Mission. As technology evolves, autonomous construction vehicles will soon become an integral part of large-scale government projects. Companies like Savik Infra that prepare early for this shift will gain a significant advantage in efficiency, quality, and delivery timelines.

In the coming years, we can expect automated excavators, robotic pavers, intelligent cranes, and self-driving trucks to become more common. These vehicles will work together through connected systems, forming fully digital construction sites where workflows are optimized through real-time data.

Conclusion

Autonomous construction vehicles are not just machines — they represent a new chapter in infrastructure development. By combining precision, safety, speed, and intelligent automation, they redefine how roads, railways, and bridges are built. For government contractors like Savik Infra, this technology can enhance productivity, maintain compliance, and ensure long-lasting public infrastructure. As automation continues to evolve, the construction sites of tomorrow will be smarter, safer, and more efficient — powered by machines that work without operators, guided entirely by technology.

OUR LATEST NEWS

OUR LATEST NEWS

OUR LATEST NEWS