BLOG DETAILS

BLOG DETAILS

BLOG DETAILS

Smart Infrastructure: Integrating Automation into Industrial Logistics Systems

Smart Infrastructure: Integrating Automation into Industrial Logistics Systems

Smart Infrastructure: Integrating Automation into Industrial Logistics Systems

Feb 12, 2026

/

savik infra

/

8 min

Feb 12, 2026

/

savik infra

/

8 min

Feb 12, 2026

/

savik infra

/

8 min

Introduction: The Rise of Smart Infrastructure in India

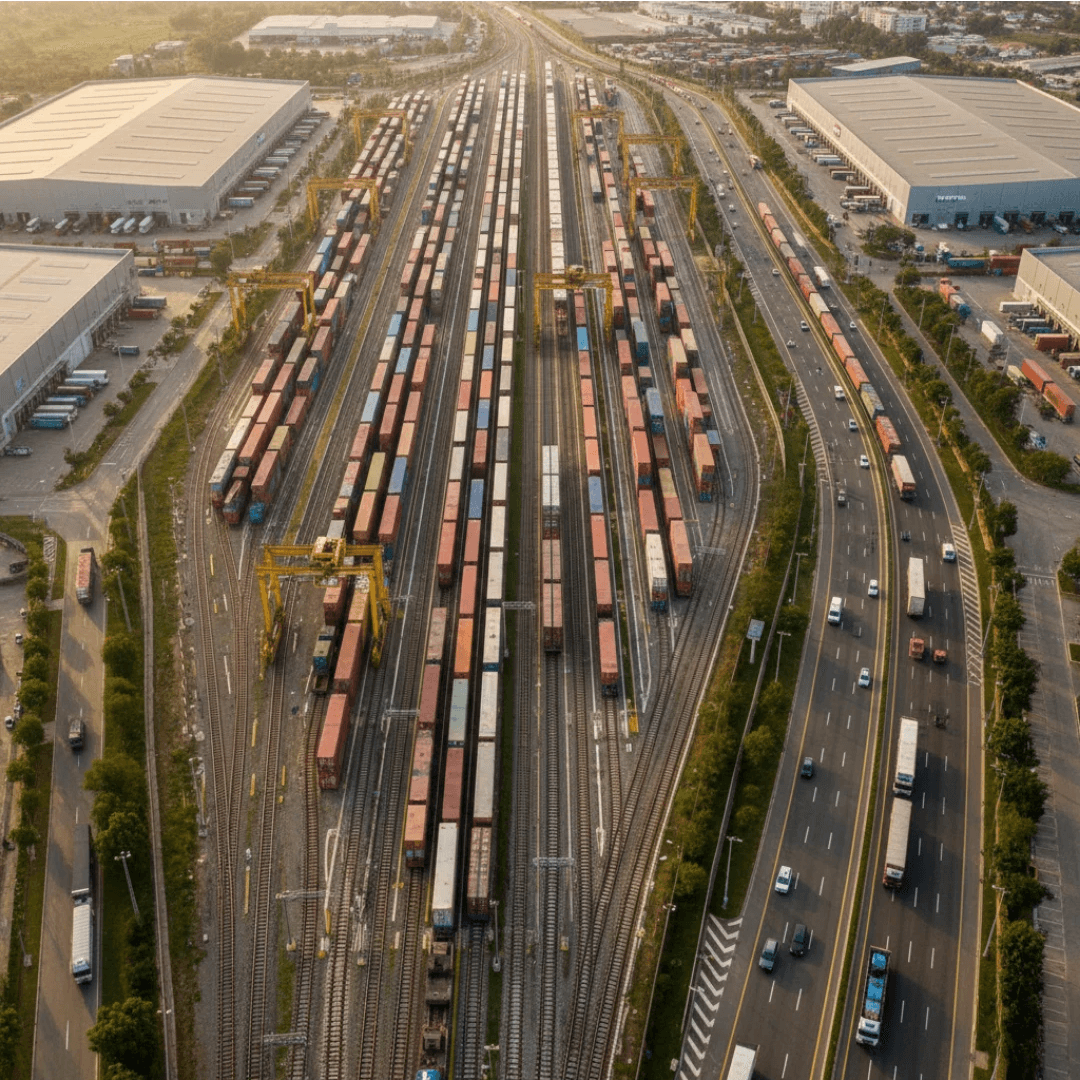

India’s industrial and logistics landscape is undergoing a technological transformation. As freight volumes increase and supply chains grow more complex, traditional infrastructure models are no longer sufficient. Smart infrastructure in industrial logistics systems is emerging as the next phase of development—where automation, digital intelligence, and connectivity redefine operational efficiency.

With modernization efforts led by institutions such as Indian Railways, and large-scale freight optimization initiatives, automation is becoming central to infrastructure planning. Industrial players are now prioritizing automated freight handling systems, real-time tracking, predictive analytics, and intelligent rail integration to remain competitive in a rapidly evolving market.

Smart infrastructure is not just about digital tools—it represents a shift toward efficiency-driven, technology-enabled industrial growth.

Understanding Automation in Industrial Logistics

Automation in industrial logistics involves integrating advanced technologies such as IoT sensors, automated material handling systems, AI-based analytics, robotics, and digital control platforms into physical infrastructure. In rail-linked logistics systems, automation enhances wagon loading efficiency, yard management, cargo tracking, and operational coordination.

Modern private railway sidings and freight terminals are increasingly equipped with automated loading conveyors, RFID-based cargo tracking, and centralized monitoring dashboards. These systems reduce human error, improve turnaround time, and optimize freight movement.

The result is a seamless integration between physical infrastructure and digital intelligence—forming the foundation of smart industrial logistics infrastructure in India

Introduction: The Rise of Smart Infrastructure in India

India’s industrial and logistics landscape is undergoing a technological transformation. As freight volumes increase and supply chains grow more complex, traditional infrastructure models are no longer sufficient. Smart infrastructure in industrial logistics systems is emerging as the next phase of development—where automation, digital intelligence, and connectivity redefine operational efficiency.

With modernization efforts led by institutions such as Indian Railways, and large-scale freight optimization initiatives, automation is becoming central to infrastructure planning. Industrial players are now prioritizing automated freight handling systems, real-time tracking, predictive analytics, and intelligent rail integration to remain competitive in a rapidly evolving market.

Smart infrastructure is not just about digital tools—it represents a shift toward efficiency-driven, technology-enabled industrial growth.

Understanding Automation in Industrial Logistics

Automation in industrial logistics involves integrating advanced technologies such as IoT sensors, automated material handling systems, AI-based analytics, robotics, and digital control platforms into physical infrastructure. In rail-linked logistics systems, automation enhances wagon loading efficiency, yard management, cargo tracking, and operational coordination.

Modern private railway sidings and freight terminals are increasingly equipped with automated loading conveyors, RFID-based cargo tracking, and centralized monitoring dashboards. These systems reduce human error, improve turnaround time, and optimize freight movement.

The result is a seamless integration between physical infrastructure and digital intelligence—forming the foundation of smart industrial logistics infrastructure in India

Introduction: The Rise of Smart Infrastructure in India

India’s industrial and logistics landscape is undergoing a technological transformation. As freight volumes increase and supply chains grow more complex, traditional infrastructure models are no longer sufficient. Smart infrastructure in industrial logistics systems is emerging as the next phase of development—where automation, digital intelligence, and connectivity redefine operational efficiency.

With modernization efforts led by institutions such as Indian Railways, and large-scale freight optimization initiatives, automation is becoming central to infrastructure planning. Industrial players are now prioritizing automated freight handling systems, real-time tracking, predictive analytics, and intelligent rail integration to remain competitive in a rapidly evolving market.

Smart infrastructure is not just about digital tools—it represents a shift toward efficiency-driven, technology-enabled industrial growth.

Understanding Automation in Industrial Logistics

Automation in industrial logistics involves integrating advanced technologies such as IoT sensors, automated material handling systems, AI-based analytics, robotics, and digital control platforms into physical infrastructure. In rail-linked logistics systems, automation enhances wagon loading efficiency, yard management, cargo tracking, and operational coordination.

Modern private railway sidings and freight terminals are increasingly equipped with automated loading conveyors, RFID-based cargo tracking, and centralized monitoring dashboards. These systems reduce human error, improve turnaround time, and optimize freight movement.

The result is a seamless integration between physical infrastructure and digital intelligence—forming the foundation of smart industrial logistics infrastructure in India

Building home, happy hearts

Building home, happy hearts

Innovative technology with building better development

Innovative technology with building better development

Discovering possibility and transparent communication

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

Role of Rail Modernization in Smart Infrastructure

Rail infrastructure plays a pivotal role in logistics automation. The expansion of freight corridors by the Dedicated Freight Corridor Corporation of India Limited has introduced higher-capacity routes and improved operational efficiency.

Automation enhances these corridors through digital signaling systems, predictive maintenance tools, and real-time freight monitoring platforms. Integration with automated yard management systems ensures smooth cargo flow between rail, road, and warehouse facilities.

As Indian Railways continues electrification and digitalization initiatives, infrastructure developers are aligning projects with intelligent control systems and advanced monitoring technologies to build future-ready rail connectivity solutions.

Digital Integration & Real-Time Data Management

Smart infrastructure thrives on data. Real-time data analytics platforms allow industries to monitor cargo movement, inventory levels, route efficiency, and system performance. IoT-enabled sensors track wagon location, loading weight, temperature conditions, and asset utilization.

Digital dashboards centralize operational visibility, enabling proactive decision-making. Predictive analytics help anticipate equipment maintenance needs, reducing downtime and operational disruptions.

This integration of automation with data intelligence enhances reliability, scalability, and transparency across industrial logistics systems—making infrastructure more responsive and resilient.

Economic & Operational Advantages of Automation

Automated logistics infrastructure reduces manual intervention, accelerates cargo handling, and improves accuracy in freight operations. Faster wagon turnaround times and optimized yard planning contribute directly to cost savings.

Automation also enhances workplace safety by minimizing manual heavy-load handling and improving monitoring of operational risks. For large-scale industries such as steel, cement, mining, FMCG, and power generation, automation ensures consistent performance and scalability.

By integrating automation into industrial logistics systems, infrastructure developers create efficient ecosystems capable of supporting increasing freight demand while maintaining operational stability.

Role of Rail Modernization in Smart Infrastructure

Rail infrastructure plays a pivotal role in logistics automation. The expansion of freight corridors by the Dedicated Freight Corridor Corporation of India Limited has introduced higher-capacity routes and improved operational efficiency.

Automation enhances these corridors through digital signaling systems, predictive maintenance tools, and real-time freight monitoring platforms. Integration with automated yard management systems ensures smooth cargo flow between rail, road, and warehouse facilities.

As Indian Railways continues electrification and digitalization initiatives, infrastructure developers are aligning projects with intelligent control systems and advanced monitoring technologies to build future-ready rail connectivity solutions.

Digital Integration & Real-Time Data Management

Smart infrastructure thrives on data. Real-time data analytics platforms allow industries to monitor cargo movement, inventory levels, route efficiency, and system performance. IoT-enabled sensors track wagon location, loading weight, temperature conditions, and asset utilization.

Digital dashboards centralize operational visibility, enabling proactive decision-making. Predictive analytics help anticipate equipment maintenance needs, reducing downtime and operational disruptions.

This integration of automation with data intelligence enhances reliability, scalability, and transparency across industrial logistics systems—making infrastructure more responsive and resilient.

Economic & Operational Advantages of Automation

Automated logistics infrastructure reduces manual intervention, accelerates cargo handling, and improves accuracy in freight operations. Faster wagon turnaround times and optimized yard planning contribute directly to cost savings.

Automation also enhances workplace safety by minimizing manual heavy-load handling and improving monitoring of operational risks. For large-scale industries such as steel, cement, mining, FMCG, and power generation, automation ensures consistent performance and scalability.

By integrating automation into industrial logistics systems, infrastructure developers create efficient ecosystems capable of supporting increasing freight demand while maintaining operational stability.

Role of Rail Modernization in Smart Infrastructure

Rail infrastructure plays a pivotal role in logistics automation. The expansion of freight corridors by the Dedicated Freight Corridor Corporation of India Limited has introduced higher-capacity routes and improved operational efficiency.

Automation enhances these corridors through digital signaling systems, predictive maintenance tools, and real-time freight monitoring platforms. Integration with automated yard management systems ensures smooth cargo flow between rail, road, and warehouse facilities.

As Indian Railways continues electrification and digitalization initiatives, infrastructure developers are aligning projects with intelligent control systems and advanced monitoring technologies to build future-ready rail connectivity solutions.

Digital Integration & Real-Time Data Management

Smart infrastructure thrives on data. Real-time data analytics platforms allow industries to monitor cargo movement, inventory levels, route efficiency, and system performance. IoT-enabled sensors track wagon location, loading weight, temperature conditions, and asset utilization.

Digital dashboards centralize operational visibility, enabling proactive decision-making. Predictive analytics help anticipate equipment maintenance needs, reducing downtime and operational disruptions.

This integration of automation with data intelligence enhances reliability, scalability, and transparency across industrial logistics systems—making infrastructure more responsive and resilient.

Economic & Operational Advantages of Automation

Automated logistics infrastructure reduces manual intervention, accelerates cargo handling, and improves accuracy in freight operations. Faster wagon turnaround times and optimized yard planning contribute directly to cost savings.

Automation also enhances workplace safety by minimizing manual heavy-load handling and improving monitoring of operational risks. For large-scale industries such as steel, cement, mining, FMCG, and power generation, automation ensures consistent performance and scalability.

By integrating automation into industrial logistics systems, infrastructure developers create efficient ecosystems capable of supporting increasing freight demand while maintaining operational stability.

India’s industrial and logistics landscape is undergoing a technological transformation.

India’s industrial and logistics landscape is undergoing a technological transformation.

India’s industrial and logistics landscape is undergoing a technological transformation.

India’s industrial and logistics landscape is undergoing a technological transformation.

Sustainability Through Smart Infrastructure

Automation contributes to sustainability by optimizing energy usage and reducing waste. Efficient scheduling minimizes idle time for freight trains and equipment, lowering fuel consumption and emissions.

Intelligent route planning and predictive maintenance reduce resource wastage and extend asset life cycles. Electrified rail systems combined with automated operations further support environmental responsibility while improving logistics efficiency.

Smart infrastructure therefore aligns operational excellence with sustainable development goals—strengthening India’s industrial backbone without compromising environmental standards.

The Future of Smart Industrial Logistics in India

India’s ambition to become a global manufacturing hub depends on efficient and technology-driven logistics systems. As freight volumes grow and supply chains become increasingly complex, automation will become a necessity rather than a competitive advantage.

Infrastructure developers must integrate automation at every stage—from railway siding planning and yard design to digital monitoring systems and multimodal coordination. Investment in smart logistics infrastructure today ensures long-term adaptability and resilience.

The future of industrial logistics lies in intelligent integration—where infrastructure, automation, and data-driven planning operate as a unified ecosystem.

Conclusion

Smart infrastructure is redefining industrial logistics systems in India. By integrating automation, digital intelligence, and advanced rail connectivity, infrastructure developers are building efficient, scalable, and future-ready logistics ecosystems.

As modernization initiatives continue across freight corridors and rail networks, automation will remain central to improving productivity, reducing costs, and strengthening industrial competitiveness.

For forward-looking infrastructure leaders, embracing automation is not merely an upgrade—it is a strategic investment in the future of industrial growth.

Sustainability Through Smart Infrastructure

Automation contributes to sustainability by optimizing energy usage and reducing waste. Efficient scheduling minimizes idle time for freight trains and equipment, lowering fuel consumption and emissions.

Intelligent route planning and predictive maintenance reduce resource wastage and extend asset life cycles. Electrified rail systems combined with automated operations further support environmental responsibility while improving logistics efficiency.

Smart infrastructure therefore aligns operational excellence with sustainable development goals—strengthening India’s industrial backbone without compromising environmental standards.

The Future of Smart Industrial Logistics in India

India’s ambition to become a global manufacturing hub depends on efficient and technology-driven logistics systems. As freight volumes grow and supply chains become increasingly complex, automation will become a necessity rather than a competitive advantage.

Infrastructure developers must integrate automation at every stage—from railway siding planning and yard design to digital monitoring systems and multimodal coordination. Investment in smart logistics infrastructure today ensures long-term adaptability and resilience.

The future of industrial logistics lies in intelligent integration—where infrastructure, automation, and data-driven planning operate as a unified ecosystem.

Conclusion

Smart infrastructure is redefining industrial logistics systems in India. By integrating automation, digital intelligence, and advanced rail connectivity, infrastructure developers are building efficient, scalable, and future-ready logistics ecosystems.

As modernization initiatives continue across freight corridors and rail networks, automation will remain central to improving productivity, reducing costs, and strengthening industrial competitiveness.

For forward-looking infrastructure leaders, embracing automation is not merely an upgrade—it is a strategic investment in the future of industrial growth.

Sustainability Through Smart Infrastructure

Automation contributes to sustainability by optimizing energy usage and reducing waste. Efficient scheduling minimizes idle time for freight trains and equipment, lowering fuel consumption and emissions.

Intelligent route planning and predictive maintenance reduce resource wastage and extend asset life cycles. Electrified rail systems combined with automated operations further support environmental responsibility while improving logistics efficiency.

Smart infrastructure therefore aligns operational excellence with sustainable development goals—strengthening India’s industrial backbone without compromising environmental standards.

The Future of Smart Industrial Logistics in India

India’s ambition to become a global manufacturing hub depends on efficient and technology-driven logistics systems. As freight volumes grow and supply chains become increasingly complex, automation will become a necessity rather than a competitive advantage.

Infrastructure developers must integrate automation at every stage—from railway siding planning and yard design to digital monitoring systems and multimodal coordination. Investment in smart logistics infrastructure today ensures long-term adaptability and resilience.

The future of industrial logistics lies in intelligent integration—where infrastructure, automation, and data-driven planning operate as a unified ecosystem.

Conclusion

Smart infrastructure is redefining industrial logistics systems in India. By integrating automation, digital intelligence, and advanced rail connectivity, infrastructure developers are building efficient, scalable, and future-ready logistics ecosystems.

As modernization initiatives continue across freight corridors and rail networks, automation will remain central to improving productivity, reducing costs, and strengthening industrial competitiveness.

For forward-looking infrastructure leaders, embracing automation is not merely an upgrade—it is a strategic investment in the future of industrial growth.

OUR LATEST NEWS

OUR LATEST NEWS

OUR LATEST NEWS