BLOG DETAILS

BLOG DETAILS

BLOG DETAILS

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Oct 10, 2025

/

Team Savik Infra

/

8 min

Oct 10, 2025

/

Team Savik Infra

/

8 min

Oct 10, 2025

/

Team Savik Infra

/

8 min

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

In the world of infrastructure, quality isn’t just a goal — it’s a constant practice. Every bridge, platform, or structure stands as a reflection of the discipline, precision, and integrity that go into its making.

At Savik Infra, quality is not inspected at the end — it’s built in from the very beginning.

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

In the world of infrastructure, quality isn’t just a goal — it’s a constant practice. Every bridge, platform, or structure stands as a reflection of the discipline, precision, and integrity that go into its making.

At Savik Infra, quality is not inspected at the end — it’s built in from the very beginning.

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

In the world of infrastructure, quality isn’t just a goal — it’s a constant practice. Every bridge, platform, or structure stands as a reflection of the discipline, precision, and integrity that go into its making.

At Savik Infra, quality is not inspected at the end — it’s built in from the very beginning.

Building home, happy hearts

Building home, happy hearts

Innovative technology with building better development

Innovative technology with building better development

Discovering possibility and transparent communication

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

Building home, happy hearts

Innovative technology with building better development

Discovering possibility and transparent communication

The ability to turnaround costing with sustainable construction

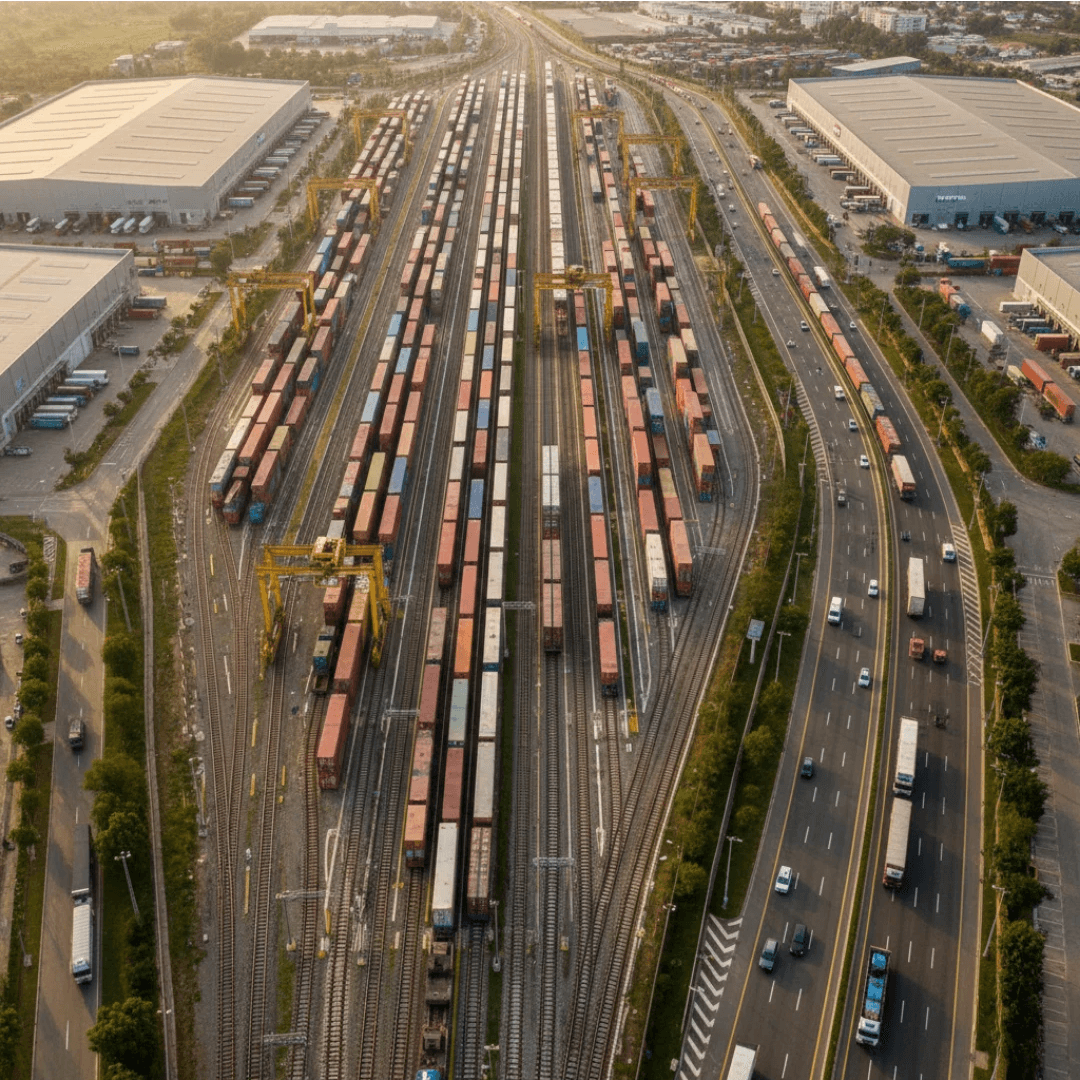

Setting New Standards in Indian Infrastructure

As India’s infrastructure network expands, especially under the massive growth of the Indian Railways, maintaining consistent quality across sites has become one of the most critical challenges for engineering firms.

Savik Infra takes pride in being one of the few organizations that treat quality control and inspection as an ongoing, everyday process — not a one-time checkpoint.

From platform wall constructions to heavy fabrication for railway structures, our teams handle inspections, material validations, and structural tests at multiple sites across India every single day. This continuous monitoring ensures that every component — from design to final welding — meets the highest safety, durability, and performance standards set by organizations such as the Research Designs & Standards Organisation (RDSO).

Quality as a Culture, Not a Department

At Savik Infra, quality assurance isn’t limited to a specialized team. It’s embedded in the mindset of every engineer, fabricator, and supervisor working on-site.

Each stage of our projects — design, procurement, fabrication, and erection — involves strict internal checks, followed by third-party and client-side validations.

Setting New Standards in Indian Infrastructure

As India’s infrastructure network expands, especially under the massive growth of the Indian Railways, maintaining consistent quality across sites has become one of the most critical challenges for engineering firms.

Savik Infra takes pride in being one of the few organizations that treat quality control and inspection as an ongoing, everyday process — not a one-time checkpoint.

From platform wall constructions to heavy fabrication for railway structures, our teams handle inspections, material validations, and structural tests at multiple sites across India every single day. This continuous monitoring ensures that every component — from design to final welding — meets the highest safety, durability, and performance standards set by organizations such as the Research Designs & Standards Organisation (RDSO).

Quality as a Culture, Not a Department

At Savik Infra, quality assurance isn’t limited to a specialized team. It’s embedded in the mindset of every engineer, fabricator, and supervisor working on-site.

Each stage of our projects — design, procurement, fabrication, and erection — involves strict internal checks, followed by third-party and client-side validations.

Setting New Standards in Indian Infrastructure

As India’s infrastructure network expands, especially under the massive growth of the Indian Railways, maintaining consistent quality across sites has become one of the most critical challenges for engineering firms.

Savik Infra takes pride in being one of the few organizations that treat quality control and inspection as an ongoing, everyday process — not a one-time checkpoint.

From platform wall constructions to heavy fabrication for railway structures, our teams handle inspections, material validations, and structural tests at multiple sites across India every single day. This continuous monitoring ensures that every component — from design to final welding — meets the highest safety, durability, and performance standards set by organizations such as the Research Designs & Standards Organisation (RDSO).

Quality as a Culture, Not a Department

At Savik Infra, quality assurance isn’t limited to a specialized team. It’s embedded in the mindset of every engineer, fabricator, and supervisor working on-site.

Each stage of our projects — design, procurement, fabrication, and erection — involves strict internal checks, followed by third-party and client-side validations.

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

Quality in Every Weld: Inside Savik Infra’s Rigorous Inspection and Validation Process

This rigorous process ensures that all our structures are:

Accurate in design execution

Reliable in long-term operation

Compliant with Indian Railway standards and specifications

Safe under dynamic and static load conditions

Our aim is simple: to ensure that every inspection, every day, at every site contributes to a stronger, safer India.

RDSO Standards: The Benchmark of Reliability

For projects associated with the Indian Railways, RDSO standards are the backbone of structural safety and consistency.

Savik Infra’s quality teams are trained to interpret, apply, and meet these benchmarks with precision.

From fabrication weld tests to non-destructive testing (NDT), and from material traceability to alignment verification, each aspect undergoes a series of validations before approval.

By treating every RDSO inspection as part of our daily rhythm, we ensure that compliance becomes second nature — not an event that disrupts our workflow.

Nationwide Operations, Unified Standards

With ongoing projects spread across multiple regions of India, maintaining consistency in quality is a challenge that few can master.

Savik Infra achieves this through:

Centralized quality protocols that every site follows.

A dedicated QA team that audits projects regularly.

Use of digital inspection records and real-time communication between fabrication yards and project managers.

This system allows us to deliver uniform reliability, whether it’s a railway structure in Rajasthan or a foundation build in Gujarat.

The People Behind the Precision

While processes define structure, it’s the people who define standards.

Savik Infra’s engineers and supervisors bring a blend of technical expertise, accountability, and on-ground experience that ensures flawless execution.

Their dedication and understanding of railway and infrastructure standards make them the real backbone of our promise — to build with precision, passion, and purpose.

Conclusion: Quality is Our Constant

Passing inspections is not a milestone for Savik Infra — it’s a reflection of what we do every day.

Through disciplined processes, constant learning, and an unwavering focus on standards, we continue to build the infrastructure that keeps India moving forward — safely, reliably, and sustainably.

Because for us, quality is not an event — it’s our everyday foundation.

This rigorous process ensures that all our structures are:

Accurate in design execution

Reliable in long-term operation

Compliant with Indian Railway standards and specifications

Safe under dynamic and static load conditions

Our aim is simple: to ensure that every inspection, every day, at every site contributes to a stronger, safer India.

RDSO Standards: The Benchmark of Reliability

For projects associated with the Indian Railways, RDSO standards are the backbone of structural safety and consistency.

Savik Infra’s quality teams are trained to interpret, apply, and meet these benchmarks with precision.

From fabrication weld tests to non-destructive testing (NDT), and from material traceability to alignment verification, each aspect undergoes a series of validations before approval.

By treating every RDSO inspection as part of our daily rhythm, we ensure that compliance becomes second nature — not an event that disrupts our workflow.

Nationwide Operations, Unified Standards

With ongoing projects spread across multiple regions of India, maintaining consistency in quality is a challenge that few can master.

Savik Infra achieves this through:

Centralized quality protocols that every site follows.

A dedicated QA team that audits projects regularly.

Use of digital inspection records and real-time communication between fabrication yards and project managers.

This system allows us to deliver uniform reliability, whether it’s a railway structure in Rajasthan or a foundation build in Gujarat.

The People Behind the Precision

While processes define structure, it’s the people who define standards.

Savik Infra’s engineers and supervisors bring a blend of technical expertise, accountability, and on-ground experience that ensures flawless execution.

Their dedication and understanding of railway and infrastructure standards make them the real backbone of our promise — to build with precision, passion, and purpose.

Conclusion: Quality is Our Constant

Passing inspections is not a milestone for Savik Infra — it’s a reflection of what we do every day.

Through disciplined processes, constant learning, and an unwavering focus on standards, we continue to build the infrastructure that keeps India moving forward — safely, reliably, and sustainably.

Because for us, quality is not an event — it’s our everyday foundation.

This rigorous process ensures that all our structures are:

Accurate in design execution

Reliable in long-term operation

Compliant with Indian Railway standards and specifications

Safe under dynamic and static load conditions

Our aim is simple: to ensure that every inspection, every day, at every site contributes to a stronger, safer India.

RDSO Standards: The Benchmark of Reliability

For projects associated with the Indian Railways, RDSO standards are the backbone of structural safety and consistency.

Savik Infra’s quality teams are trained to interpret, apply, and meet these benchmarks with precision.

From fabrication weld tests to non-destructive testing (NDT), and from material traceability to alignment verification, each aspect undergoes a series of validations before approval.

By treating every RDSO inspection as part of our daily rhythm, we ensure that compliance becomes second nature — not an event that disrupts our workflow.

Nationwide Operations, Unified Standards

With ongoing projects spread across multiple regions of India, maintaining consistency in quality is a challenge that few can master.

Savik Infra achieves this through:

Centralized quality protocols that every site follows.

A dedicated QA team that audits projects regularly.

Use of digital inspection records and real-time communication between fabrication yards and project managers.

This system allows us to deliver uniform reliability, whether it’s a railway structure in Rajasthan or a foundation build in Gujarat.

The People Behind the Precision

While processes define structure, it’s the people who define standards.

Savik Infra’s engineers and supervisors bring a blend of technical expertise, accountability, and on-ground experience that ensures flawless execution.

Their dedication and understanding of railway and infrastructure standards make them the real backbone of our promise — to build with precision, passion, and purpose.

Conclusion: Quality is Our Constant

Passing inspections is not a milestone for Savik Infra — it’s a reflection of what we do every day.

Through disciplined processes, constant learning, and an unwavering focus on standards, we continue to build the infrastructure that keeps India moving forward — safely, reliably, and sustainably.

Because for us, quality is not an event — it’s our everyday foundation.

OUR LATEST NEWS

OUR LATEST NEWS

OUR LATEST NEWS